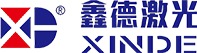

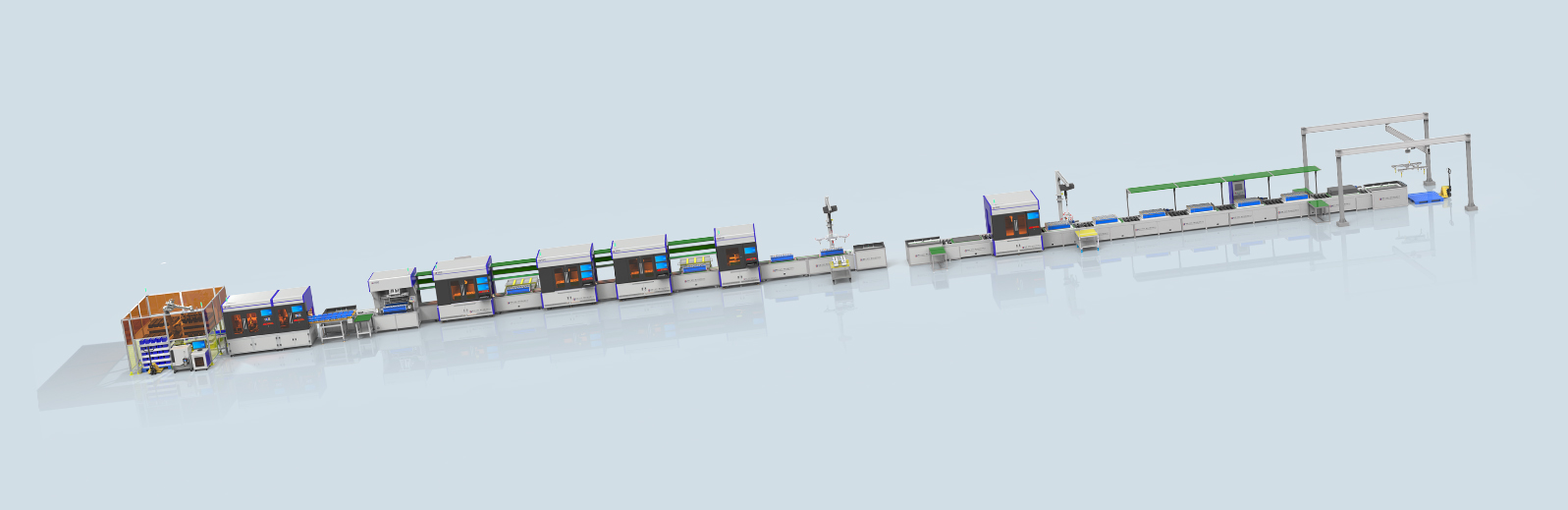

New energy PACK whole line solution provider

Products & Solutions

New energy PACK whole line solution provider

- Square shell battery PACK production line

- Longmen laser welder station

- Six axis manipulator laser welding machine

Square shell battery PACK production line

Chip as the core components of electronic products, Shengxiong Laser has always studied its best processing program. The self-developed wafer laser cutting machine, with high chip output rate and high wafer cutting precision, is the leader in the field of semiconductor chip processing.

Learn more

Longmen laser welder station

Chip as the core components of electronic products, Shengxiong Laser has always studied its best processing program. The self-developed wafer laser cutting machine, with high chip output rate and high wafer cutting precision, is the leader in the field of semiconductor chip processing.

Learn more

Six axis manipulator laser welding machine

Chip as the core components of electronic products, Shengxiong Laser has always studied its best processing program. The self-developed wafer laser cutting machine, with high chip output rate and high wafer cutting precision, is the leader in the field of semiconductor chip processing.

Learn moreAbout us

Use "Xin" Wisdom to Build Virtue

Xinde (Shenzhen) Laser Equipment Co., Ltd. is an automatic intelligent equipment technology enterprise focusing on the research and development, manufacturing and service of new energy lithium battery laser welding. The company has perfect production equipment, cutting-edge technical personnel team, perfect after-sales service system, equipment products have been widely used in many leading enterprises in the lithium battery industry, superior quality has been widely recognized and supported by customers.

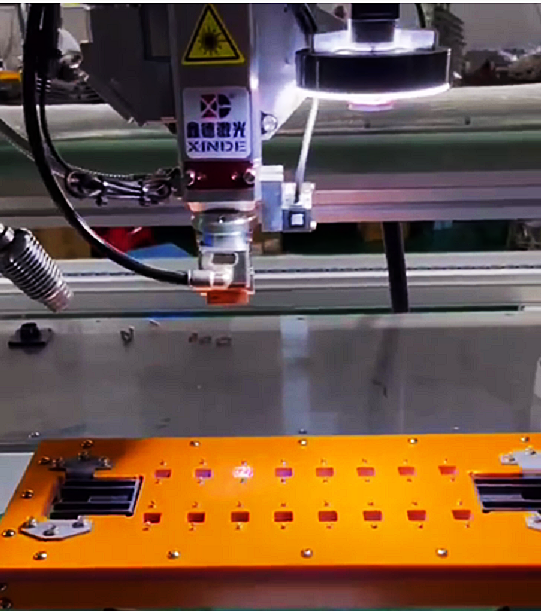

Xindel Laser intelligent equipment has a large number of practical applications in the market of lithium battery welding process from square aluminum shell sealing welding, explosion-proof valve welding, convergence plate welding, liquid injection port welding, pole village collision welding, pole lug nickel welding, rotary studs welding, Busbar module welding, covering the overall scheme equipment of power battery PACK, energy storage battery fiber pack assembly line and assembly line. Customized according to the user, in line with the user's actual production needs, site requirements of the process solution, truly achieve the battery manufacturing enterprises to provide one-stop service, committed to the national new energy lithium battery industry development to make a positive contribution.

Xinde Laser adhering to the "integrity, science, win-win, innovation, service" core values, for the user's thinking, constantly increase capital investment, improve technology research and development efforts, create a highly professional, high-quality scientific research team and after-sales team, automatically bring high efficiency, science and technology to lead the future, Xinde people continue to pursue new energy lithium battery welding intelligent equipment higher technical breakthrough, To explore and develop the future energy PACK solution provider for "high intelligent manufacturing solution" intelligent manufacturing in the field of lithium electricity.

Learn more

Xindel Laser intelligent equipment has a large number of practical applications in the market of lithium battery welding process from square aluminum shell sealing welding, explosion-proof valve welding, convergence plate welding, liquid injection port welding, pole village collision welding, pole lug nickel welding, rotary studs welding, Busbar module welding, covering the overall scheme equipment of power battery PACK, energy storage battery fiber pack assembly line and assembly line. Customized according to the user, in line with the user's actual production needs, site requirements of the process solution, truly achieve the battery manufacturing enterprises to provide one-stop service, committed to the national new energy lithium battery industry development to make a positive contribution.

Xinde Laser adhering to the "integrity, science, win-win, innovation, service" core values, for the user's thinking, constantly increase capital investment, improve technology research and development efforts, create a highly professional, high-quality scientific research team and after-sales team, automatically bring high efficiency, science and technology to lead the future, Xinde people continue to pursue new energy lithium battery welding intelligent equipment higher technical breakthrough, To explore and develop the future energy PACK solution provider for "high intelligent manufacturing solution" intelligent manufacturing in the field of lithium electricity.

20000m²Production base

20000m²Production base 50+Research and development personnel

50+Research and development personnel 3000+The customer

3000+The customer 29itemPatent for invention

29itemPatent for invention

Why choose us?

Source factory to give you the most professional is tailor-made

Technology Research and DevelopmentWith more than 10 years of research and development experienceXinde Laser R & D team has more than ten technical leaders with more than ten years of research and development experience, including mechanical design, electrical design, electrical control, process testing, installation and commissioning, assembly, etc.Inquire

Technology Research and DevelopmentWith more than 10 years of research and development experienceXinde Laser R & D team has more than ten technical leaders with more than ten years of research and development experience, including mechanical design, electrical design, electrical control, process testing, installation and commissioning, assembly, etc.Inquire Quality systemBe strict with every detailXin DE laser attaches great importance to product quality, with a standardized production workshop, the formation of the industry 139 production inspection procedures. Every detail of each process must go through strict inspection and testing to ensure that the standards are met.Inquire

Quality systemBe strict with every detailXin DE laser attaches great importance to product quality, with a standardized production workshop, the formation of the industry 139 production inspection procedures. Every detail of each process must go through strict inspection and testing to ensure that the standards are met.Inquire Service conceptA full range of fast response servicesXinde Laser fast response customer service team, including pre-sales service, sales service, after-sales service, customer training and other professional teams, to provide 7*24 hours full range of fast response service.Inquire

Service conceptA full range of fast response servicesXinde Laser fast response customer service team, including pre-sales service, sales service, after-sales service, customer training and other professional teams, to provide 7*24 hours full range of fast response service.Inquire Free trainingProfessional personnel free operation trainingIn order to ensure that customers can use the equipment efficiently and safely, customers need to send equipment operators to Xindel laser training Center for free complete equipment operation training before using the equipment.Inquire

Free trainingProfessional personnel free operation trainingIn order to ensure that customers can use the equipment efficiently and safely, customers need to send equipment operators to Xindel laser training Center for free complete equipment operation training before using the equipment.Inquire

News Updates

High intelligent manufacturing solutions

Are you looking for personalized technical support?

Customer-centric, create value for customers, 24 hours response

Inquire

-

Inquire

- Mobile

- Mobile177-2247-7738

- Tiktok

- Video

- Top